Introduction to the basic knowledge of thermal expansion valve

Guide: Expansion valve is an important part of the refrigeration system. It is generally installed between the liquid storage cylinder and the evaporator. The thermal expansion valve controls the refrigerant flow into the evaporator by controlling the superheat of the gaseous refrigerant at the outlet of the evaporator. This article mainly introduces the main basic knowledge of thermal expansion valve to facilitate everyone to better understand thermal expansion valve.

1. Brief introduction of thermal expansion valve

The thermal expansion valve realizes the throttling from the condensing pressure to the evaporating pressure, and at the same time controls the flow of the refrigerant. Although its volume is small, it has a huge effect. Its working quality directly determines the working quality of the entire system and gives the evaporator in a way Liquid supply to ensure the stable superheat of the refrigerant vapor at the outlet of the evaporator. The temperature sensing bulb must be in good contact with the suction pipe of the compressor to accurately sense the suction temperature of the compressor. It is usually filled with the same temperature as the inside of the refrigeration system. Refrigerant, so that the pressure feedback through the temperature sensor is the saturation pressure of the type of refrigerant corresponding to the compressor suction temperature. The expansion valve ensures that when the operating environment changes (such as thermal load changes), The liquid supply method of the evaporator and the temperature sensor bulb is only corrected according to the complete evaporation of the liquid refrigerant in the temperature sensor bulb at a certain temperature, which is equivalent to acting on the expansion valve diaphragm The pressure feedback from the bulb sets an upper limit, because if the surface temperature of the tube continues to increase, it will only increase the temperature of the gaseous refrigerant inside the bulb (in an overheated state), and the pressure will basically not change.

2.the role of thermal expansion valve

There are three main functions of the thermal expansion valve in the refrigeration system:

1)Throttling

The high-temperature and high-pressure liquid refrigerant condensed by the condenser is throttled and depressurized to become a low-temperature and low-pressure vapor-liquid mixture that is easy to evaporate, which enters the evaporator to evaporate and absorb external heat;

2)Control the flow of refrigerant

According to the temperature signal obtained by the temperature sensing bulb or the air box head, the expansion valve can automatically adjust the refrigerant flow into the evaporator to meet the changing needs of the refrigeration load.

3)Maintain a certain degree of overheating to prevent liquid shock and abnormal overheating

The expansion valve makes the evaporator have a certain degree of superheat by adjusting the flow rate, ensuring the effective use of the total volume of the evaporator, and avoiding liquid refrigerant entering the compressor to cause liquid hammer; at the same time, it can control the degree of superheat within a certain range to prevent abnormal overheating occur.

3.the classification of thermal expansion valve

Thermal expansion valves are divided into two structural types: internal balance and external balance according to different balance modes.

1.Structure and working principle of internally balanced expansion valve

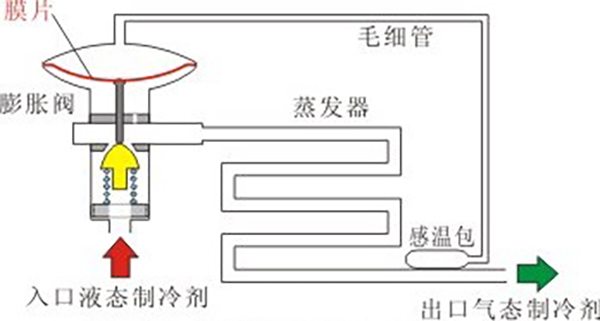

figure 1 Internal balance type F type thermal expansion valve structure diagram

Structure diagram of internally balanced F-type thermal expansion valve. The temperature sensing bulb is filled with refrigerant and placed on the outlet pipe of the evaporator. The temperature sensing bulb and the upper part of the diaphragm are connected by capillary tubes to sense the temperature of the refrigerant at the evaporator outlet, and the pressure at the evaporator inlet is felt under the diaphragm. If the air conditioning load increases and the hydraulic refrigerant is evaporated in the evaporator ahead of time, the temperature of the refrigerant at the outlet of the evaporator will rise, and the pressure on the diaphragm will increase, pushing the valve stem to increase the opening of the expansion valve and entering the evaporator. The refrigerant flow increases, the cooling capacity increases; if the air-conditioning load decreases, the refrigerant temperature at the outlet of the evaporator decreases, and the valve opening is reduced by the same principle of action, thereby controlling the refrigerant flow.

2.Structure and working principle of externally balanced expansion valve

The H-type thermal expansion valve has four ports to connect to the refrigeration system, two of which are the same as ordinary thermal expansion valves, one is connected to the storage dryer, one is connected to the evaporator inlet; the other two ports, one is connected to the evaporator outlet, and the other Connect the compressor inlet. The temperature sensing bulb is directly in the refrigerant airflow at the outlet of the evaporator. Because the expansion valve eliminates the temperature sensing bulb, capillary tube and external balance pipe in the F-type thermal expansion valve, the adjustment sensitivity is improved, the structure is compact, and the vibration resistance is reliable.

It should be noted that the principle of the externally balanced expansion valve is basically the same as that of the balanced expansion valve. The main difference is: the inner balanced expansion valve diaphragm feels the evaporator inlet pressure; the outer balanced expansion valve diaphragm feels What you get is the outlet pressure of the evaporator.

4. Thermal expansion valve adjustment process

1.Check before adjustment of thermal expansion valve

Before adjusting the thermal expansion valve, it must be confirmed that the abnormal refrigeration of the equipment is caused by the deviation of the thermal expansion valve from the operating point, and not caused by other reasons such as low freon, clogging of the dryer filter, filter screen, and fan. At the same time, the correctness of the sampling signal of the temperature sensor must be ensured. The temperature sensor must be installed horizontally at 45 degrees below the return pipe. It cannot be installed directly under the pipe to prevent oil accumulation at the bottom of the pipe from affecting the temperature. Pack the right sense of temperature. It cannot be installed on a riser. Check the condenser fan control mode and try to use speed control to ensure constant condensing pressure.

2.Matters needing attention when adjusting thermal expansion valve

When adjusting the thermal expansion valve, you need to pay attention to the following aspects:

1)The adjustment of the thermal expansion valve must be carried out in the normal operating state of the refrigeration device. Since the thermometer cannot be placed on the surface of the evaporator, the suction pressure of the compressor can be used as the saturation pressure in the evaporator and the approximate evaporation temperature can be obtained by looking up the table. Use a thermometer to measure the temperature of the return air pipe and compare it with the evaporation temperature to check the superheat.

2)During the adjustment, if you feel that the degree of overheating is too small, you can turn the adjusting screw clockwise (that is, increase the spring force and reduce the opening of the thermal expansion valve) to reduce the flow; on the contrary, if you feel that the degree of overheating is too high, That is, if the liquid supply is insufficient, the adjusting screw can be turned in the opposite direction (counterclockwise) to increase the flow rate.

3)Due to the thermal inertia of the thermal expansion valve temperature sensing system in actual work, the signal transmission lag is formed, and the downward adjustment can be made after the operation is basically stable. Therefore, the entire adjustment process must be patient and meticulous, and the number of turns of the adjustment screw should not be too fast.

Article source: Weiku Electronic Market Network https://www.dzsc.com